SG Based Force Sensors

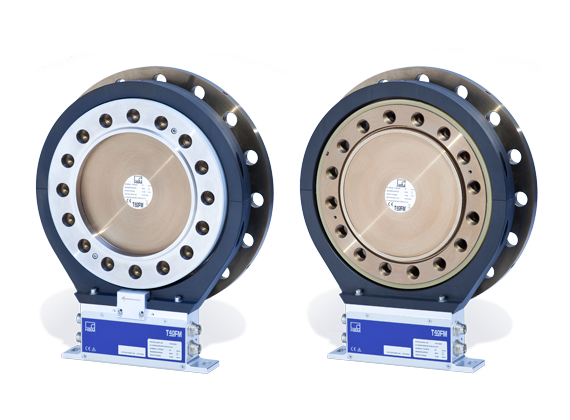

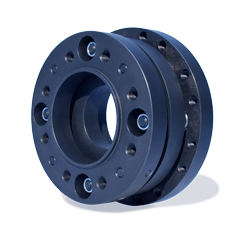

Transfer Devices for Use in Force Standard Machines

HBM Build-Up Systems: Capacities from 60 kN to 15 MN

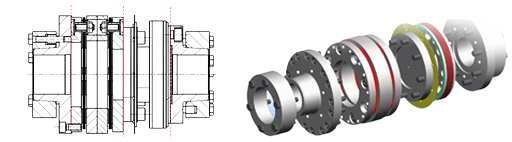

The series BU18 transfer devices comprise a three-ring torsion force, with transducers mounted parallelly. The three individual sensors can be electrically connected in parallel. Alternatively, they can also be connected to one amplifier input each.

The modular design of the design offers users significant practical advantages for system assembly: users can install individual component parts with lower weight instead of having to handle a single, very heavy sensor. Moreover, the three individual sensors can be used separately for other calibration tasks.

HBM build-up systems have been used in many research projects with the objective of deducing the behavior of systems connected in parallel with the help of the results obtained in individual calibration. In this context, the system’s outstanding repeatability has proven especially valuable. The following are some of the highlights of the build-up systems:

- HBM accuracy class: 0.03

- Accuracy class as per ISO376: 00

- Capacities: 3 MN (other, higher capacities available on request)

Read more

Force Measurement Technology- Tried and Tested a Thousand Times Over

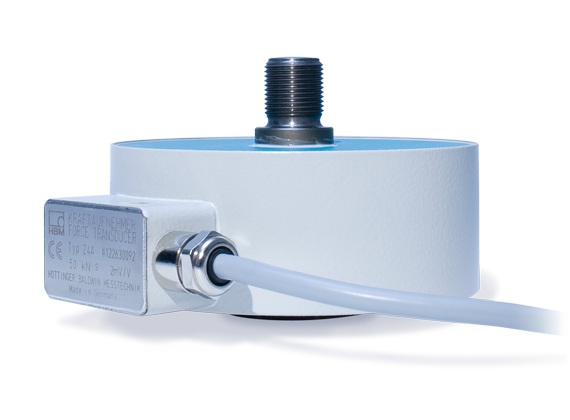

C2 Force Sensor: Reliable Compressive Force Measurement

The C2 force sensor, tried and tested over a long time, is a diaphragm sensor – a design that is very well-suited for fast measurements. This sensor, with integrated lateral force compensation, works safely even in the event of lateral forces or non-centric force application.

HBK has re-engineered the C2 series sensors for compressive force measurement to enable quick and optimized response to spare parts requirements and new designs. Different cable lengths, mounted plugs and TEDS are available, allowing for more efficient installation. In addition to the well-known passive versions of the force sensor, optional versions are now also available featuring integrated electronics and a current or voltage output (4 –20 mA or 0 – 10 V), while external dimensions remain unchanged.

- HBM accuracy class: Up to 0.1 (0.5 kN: 0.2)

- Capacities: 0.5 kN to 200 kN

Read more

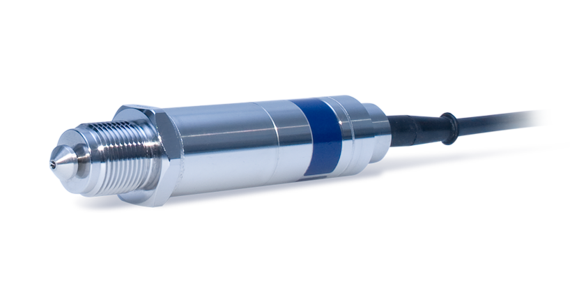

Small, Dynamic and Ready to Measure

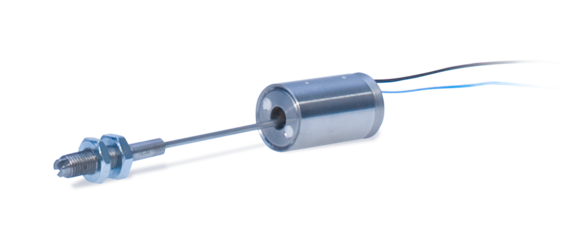

C9C Force Sensor: Miniature force transducer for compressive force measurement

The compact and cost-effective C9C type series force sensors reliably measure compressive force where space is limited. Due to their high fundamental frequency, they are suitable for very fast measurements. Like all strain gauge-based transducers, the C9C sensors also allow for static forces to be measured reliably and with long-term stability. They ensure both robustness and high load-bearing capacity due to their welded design from stainless steel.

- HBM accuracy class: 0.2

- Capacities: 50N to 50kN

- Output options: IO-Link, 0-10V, 4-20 mA

The force transducer is available with a permanently connected in-line amplifier. The transducer is calibrated as a measurement chain.

Read more

Precise, Robust and Easily Adaptable

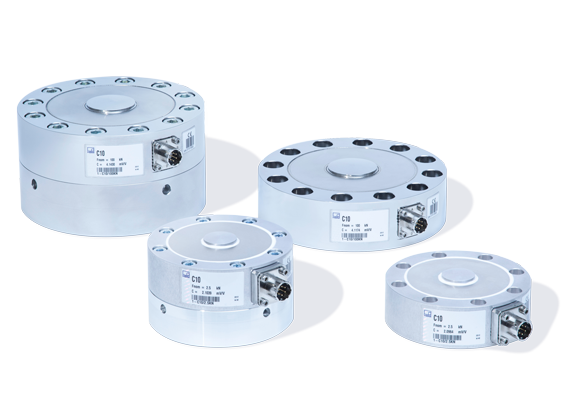

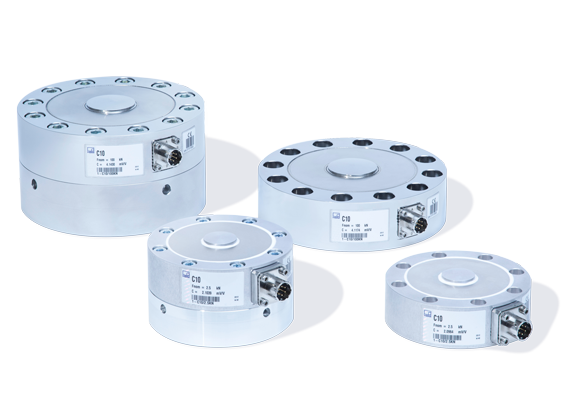

C10 Compressive Force Sensor: Maximum Precision with Outstanding Flexibility

C10 sensors are radially symmetrical compression force transducers based on special strain gauges that compensate the temperature dependence of the Young’s modulus of the measuring body. Hence, compensation elements for the temperature coefficient of sensitivity (TKC) – a necessity for conventional force sensors – can be omitted in the C10 without any loss of accuracy. The gauges are more sensitive than standard gauges and produce more than 4mV/V rated output for all steel versions of the sensor. The C10 series is a benchmark in accuracy, made from rust-free materials, and various configuration options are available for current market prices.

- HBM accuracy class: 0.02... 0.05

- Capacities: 2.5 kN to 1 MN

Read more

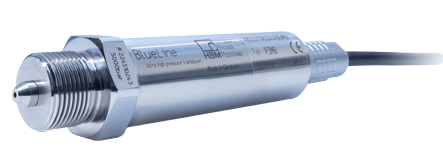

Dependable, Cost- Effective, and Precise- Also Available for Large, Compressive Forces

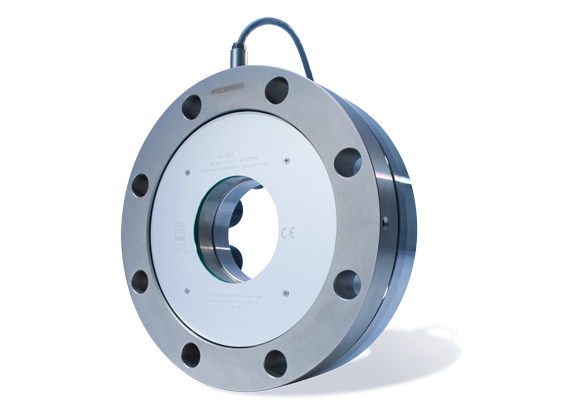

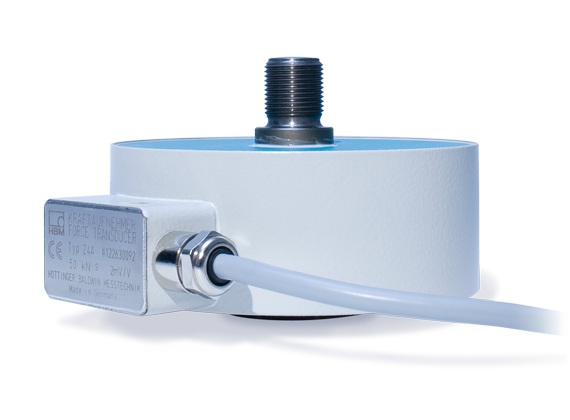

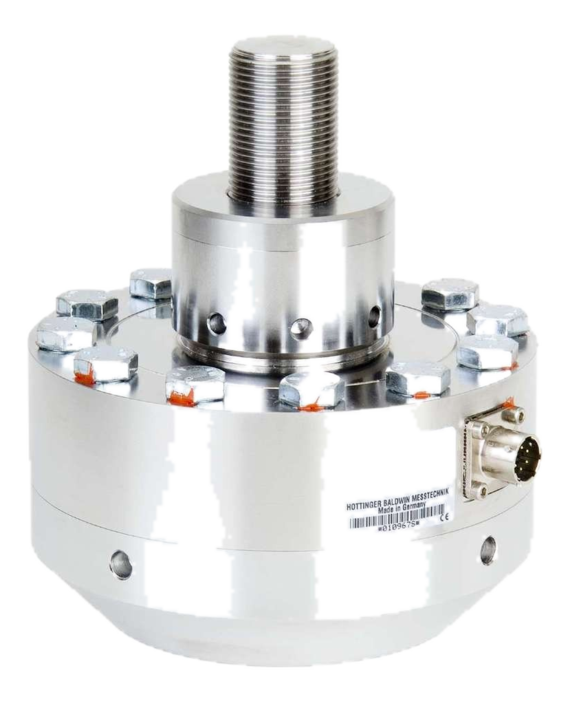

C18 Reference Force Transducer: Transfer Devices for Large Compressive Forces

The C18 reference force transducer measures compressive force based on the ring torsion principle and is, therefore, particularly insensitive to temperature gradients, lateral force and bending moment. As far as capacity is concerned, the transducer is small and light-weight, and therefore, easy to transport and install in different locations. Its hermetically sealed stainless steel design, with an IP68 degree of protection, ensures a robust performance and long-term stability.

The C18 series covers capacities ranging from 10 kN to as high as 5 MN. Besides, it meets the requirements of a transfer device for traceability of a force measurement machine to a standard. The transducer is also well-suited for use as a working sensor in calibration machines or as a working standard in companies that need to ensure dependable traceability of measuring equipment. The C18 is used in many national metrology institutes and is also well-suited to mobile applications as well as in the extremely precise determination of the center of gravity, for example, of an aircraft.

A C18 transducer is always calibrated, and comes complete with a mounting base and thrust piece. No additional load application parts are required. Overall, the C18 provides users with an extremely cost-effective solution.

- Accuracy class (ISO376): 0.5

- HBM accuracy class: 0.02

- Capacity: 10 kN to 5 MN

Read more

Precise and Economical, with Overload Protection

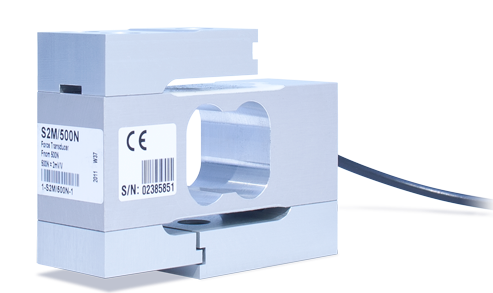

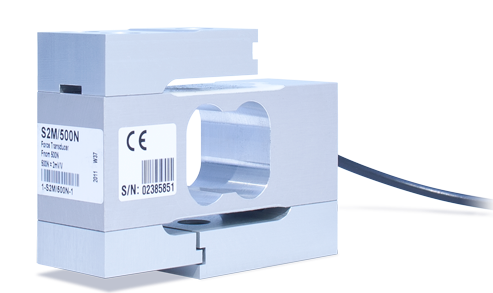

S-Shaped S2M Load Cell: Measurements From 10 N to 1 kN

The S-shaped S2M force transducer measures tensile and compressive forces and can be used for a wide variety of static and dynamic measurement applications.

The consistently high output signal of 2 mV/V guarantees a good signal-to-noise ratio. It measures very precisely even with small forces (the lowest nominal (rated) measuring range is 10 N) and returns extremely reliable results. Thanks to integrated overload protection, the S2M itself is protected against extremely strong overload in the case of machine damage.

- HBM accuracy class: 0.02

- Nominal (rated) forces: 10 N to 1 kN

Read more

Precise and Excellent Protection

S-Type S9M Load Cell: Measurements From 500 N To 50 kN

The S-shaped S9M load cell measures tensile and compressive forces and can be used for a wide variety of static and dynamic measurement applications. Thanks to its high accuracy the S9M is suitable for use in test benches and torque measurements with a lever as well as for production and monitoring tasks.

The S9M is also the right choice for difficult applications: All measuring bodies, even the one for a nominal (rated) force of 500 N, are made of stainless steel. In addition, as the S9M has a welded and therefore hermetically sealed SG installation, the force sensor load cell is rated with degree of protection IP68.

- HBM accuracy class: 0.02

- Nominal (rated) forces: 500 N to 50 kN

Read more

Tried and Tested Standard for Tensile and Compressive Forces

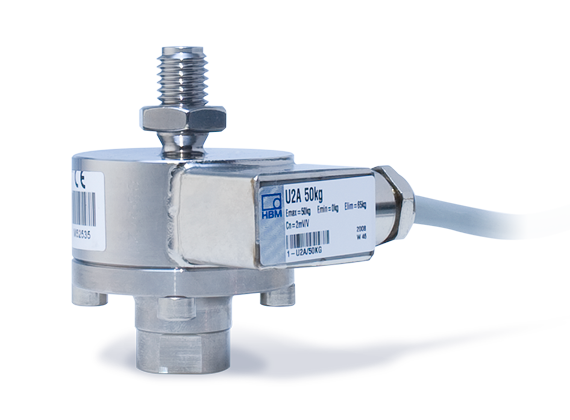

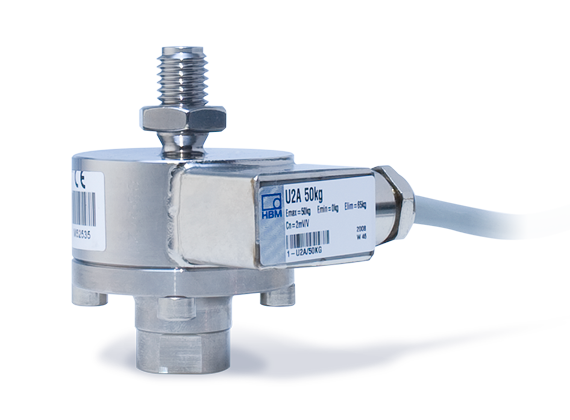

U2B force sensor: tried and tested sensor for tensile and compressive force

The proven U2B force sensor is a diaphragm transducer and is, therefore, particularly suitable for fast measurements. The sensor has a bending moment compensation to ensure that you get reliable results even if bending or lateral forces occur in the application. As a strain gauge sensor, the U2B measures both static and dynamic forces.

The U2B series has been further improved: in addition to the familiar configurations, the sensor is now also available with an integrated amplifier with current or voltage output. The dimensions remain unchanged.

- HBM accuracy class: up to 0.1 (0.5 kN: 0.2)

- Capacities: 0.5 kN to 200 kN

Read more

Easy and Quick to Mount

U3 Force Transducer: Capacities ranging from 0.5 kN to 100 kN

The U3 load cell is based on the diaphragm principle; which means the strain gauges are mounted within the load cell housing in a well protected manner. Due to the design of the supporting membrane, the U3 force sensor guarantees an exceptionally high lateral force stability of up to 100%.

The U3 has a bending moment adjustment, so that acting moments as well as transverse forces are largely compensated for. The robust design is combined with a double-sided flange connection. This allows the sensor to be mounted quickly (within a few minutes): this minimizes downtime in production. The accuracy exceeds the typical requirements in manufacturing applications.

- HBM accuracy class: 0.2

- Nominal forces: 0.5 kN to 100 kN

Read more

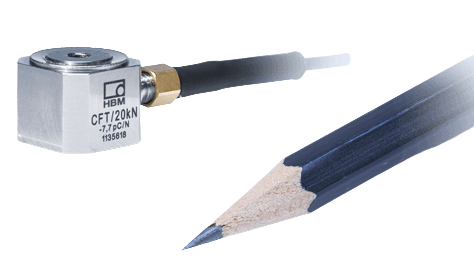

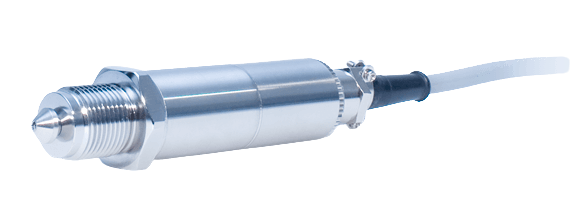

Small, Dynamic and Ready to Measure

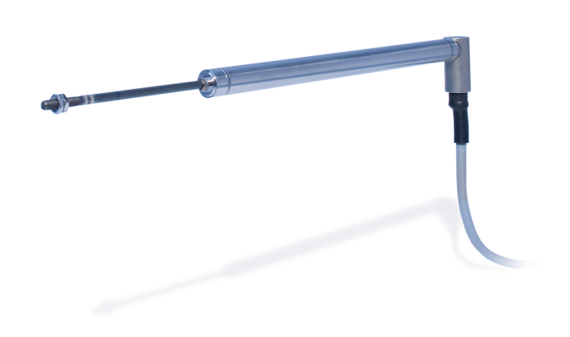

U9C Miniature Load Cell: for Measurement of Tensile and Compressive Force

The compact and cost-effective U9C type series force sensors reliably measure tensile and compressive force where space is limited. Due to their high fundamental frequency, they are suitable for very fast measurements. Like all strain gauge-based transducers, the U9C sensors also allow for static forces to be measured reliably and with long-term stability. They ensure both robustness and high load-bearing capacity due to their welded design from stainless steel.

- HBM accuracy class: 0.2

- Capacities: 50N to 50kN

- Output options: IO-Link, 0-10V, 4-20 mA

The force transducer is available with a permanently connected in-line amplifier. The transducer is calibrated as a measurement chain.

Read more

Precise, Robust and Easily Adaptable

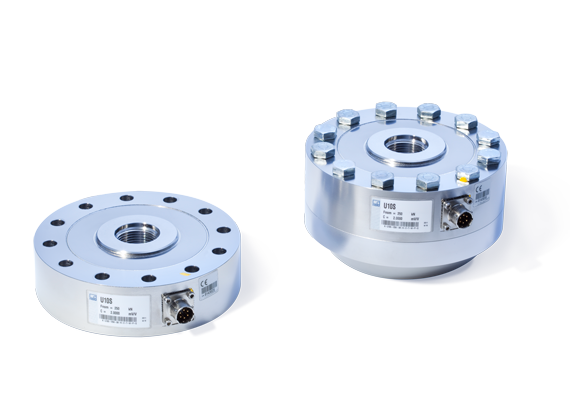

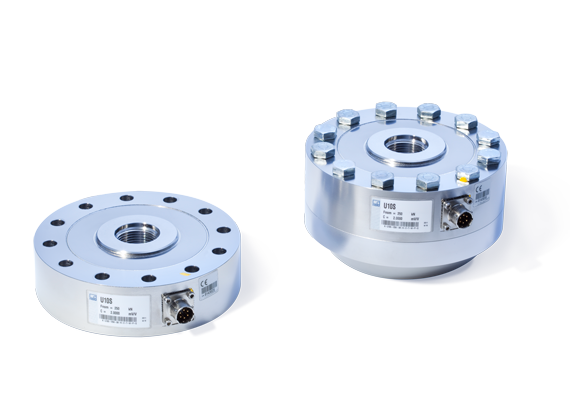

U10 Force Transducer: Capacities from 1.25 kN to 2.5 MN

The rotationally symmetric, low-profile U10 force sensor has multiple uses focusing on applications in test benches, material testing machines, and challenging tasks in production. Tensile and compressive forces can be measured.

- HBM accuracy class: 0.02 to 0.05

- Capacities: 1.25 kN to 2.5 MN

Read more

Combining Technology with Experience

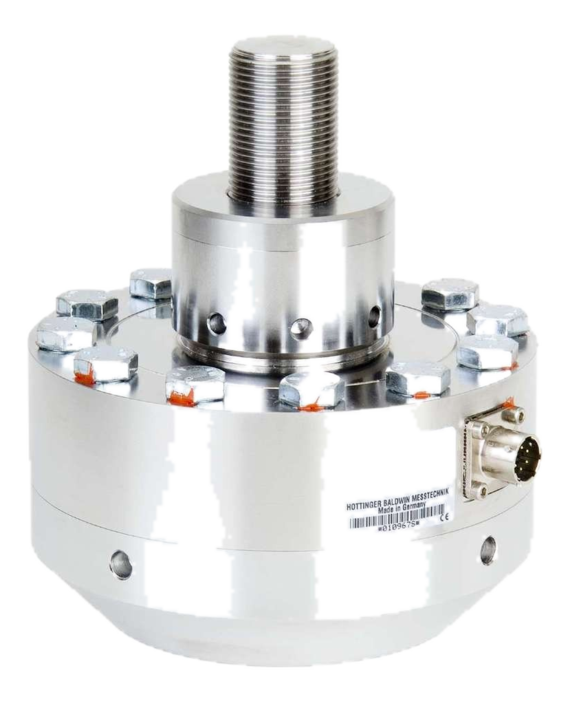

U15 Precision Load Cell: Calibrating Forces from 2.5 kN to 2.5 MN

The U15 precision load cell (reference force transducer) reliably measures tensile and compressive force up to 2.5 MN. It is ideally suited for use as the master sensor in calibration machines, for challenging tasks in test benches, and as a transfer standard (e.g. when verifying or calibrating material testing machines or taking transfer measurements to ensure traceability of calibration machines to a standard).

As the transducer is showing vey low displacement, the geometry of the test stand is also stable under load. The U15 precision load cell's high resolution, excellent signal-to-noise ratio and low measurement uncertainty are based on the transducer’s high output signal (>4 mV/V from 25 kN). This allows for optimal utilization of the subsequent electronics’ measuring range.

U15 meets the requirements of class 0.5 in accordance with ISO 376. Its radially symmetrical design makes the sensor insensitive to temperature gradients. The U15 precision load cell is very robust due to its high IP67 degree of protection and the use of stainless steel materials.

- Accuracy class (per ISO 376:2011): 0.5 in the range of 10% and 100% of the nominal load

- HBM accuracy class: 0.02 to 0.05

- Capacities: 2.5 kN to 2.5 MN

Read more

Small, Robust, Dynamic and Easy to Assemble

U93 Force Transducer: Capacities ranging from 1 kN to 50 kN

U93 is a miniature force transducer, designed in a diaphragm principle with high stiffness and is therefore an ideal choice for fast load measurements. The load cell has very small dimensions, and is easy to integrate. The mechanical connection is made by means of a flange-mounted screw connection on both sides. Thus, the assembly is very easy to carry out.

For applications where the speed and size of the sensor are important, the U93 is a more cost-effective alternative to piezoelectric sensors. Like all HBM sensors, the U93 is easy to configure and thus adapts itself even to demanding conditions. The design with support diaphragms makes the sensor exceptionally robust and resistant to lateral forces. In addition, there is an important detail for the production environment: the cable of the U93 is drag chain-compatible and oil-resistant.

- HBM accuracy class: 0.5 ... 0.8

- Nominal forces: 1 kN ... 50 kN

Read more

Reference Force Transducer and Transfer Standard

Z4A Reference Force Transducer: Calibrating and Measuring Precisely in a Range between 20 kN and 500 kN

The transfer standards (with regard to reference force transducers) of the Z4A series come with a monolithic design, i.e., the spring element constitutes one piece. The Z4A force transducers are produced in compliance with high manufacturing standards—a determining factor for the transfer standards’ small hysteresis and excellent reproducibility.

The Z4A transducers have four measuring points, each of which is offset from the other by 90 degrees. This facilitates bending moment compensation and makes the sensor exceedingly insensitive to bending moments.

ISO376-compliant mounting accessories for tensile and compressive force are available to complement the Z4A.

- Accuracy class (ISO 376): 00 (0.5 with 500 kN)

- HBM accuracy class: 0.02

- Capacities: between 20 kN and 500 kN

Read more

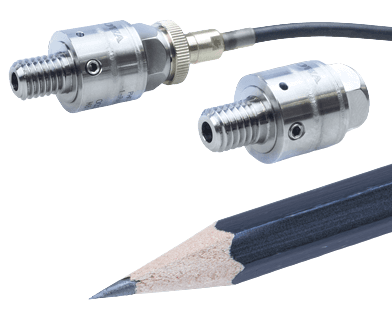

Force Transducer for Challenging Calibration Tasks

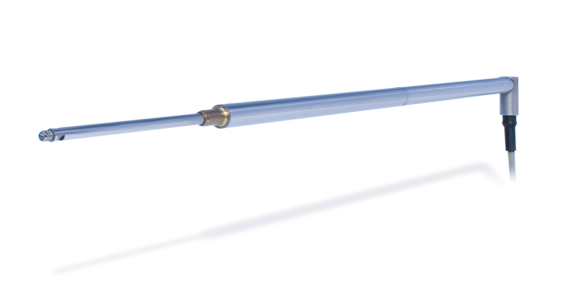

Z30A Reference Force Transducer: For Calibration and Precise Measurements Up To 10 kN

The Z30A reference force transducer measures small tensile and compressive forces with extremely high precision. This is why Z30A is frequently used where high precision is needed; as a reference transducer in calibration machines, for transfer measurements in calibration machines and as a working standard.

The Z30A reference transducer exceeds the requirements of the highest accuracy class (00) specified in ISO 376. The electrical connection is made via connectors at the housing and the base plate. Depending on the installation situation, force shunts caused by the measurement cable can be prevented. All sensors up to 1 kN capacity have an overload stop and are protected in case of faulty operations.

- Accuracy class (ISO 376): 00

- HBM accuracy class: 0.02

- Capacities: from 50 N to 10 kN

Read more