Process Equipment for Weighing, Feeding & Screening

Weighing, Feeding, Conveying, Screening, Automation, and Air Filtration Products

From Schenck Process Europe GmbH - global technology market leader in applied measuring technology

Weighing & Feeding Systems

MechaTron 3-A Feeder - Volumetric and Gravimetric Sanitary Feeder designed for sanitary applications

- Volumetric and Gravimetric Sanitary Feeder designed for sanitary applications

The MechaTron 3-A screw feeder was designed specifically for use in food and dairy industry process applications where equipment must meet 3-A sanitary levels or equivalent. All welds, radii, seals, surface finishes, gaskets, and contact and non-contact materials meet 3-A standards.

MechaTron® 3-A Screw Feeder Features:

- 3-A accepted feeder for food, dairy and and sanitary feeding applications

- Crack and crevice-free contact surfaces

- FDA compliant internal feed hopper

- Volumetric and gravimetric configurations for feed rates up to 330 ft³ (9,300 l) per hour

ProFlex C Feeders- Loss in Weight Feeder for the Compound Industry

A Feeder range with space saving design, low-maintenance and flexibility

The ProFlex ® C material feeder range consists of four different feeder sizes, to meet the varying material requirements of the Plastic compound and masterbatch industries. The range includes variants for feed rates of up to 6000dm3/h, 3000dm3/h, 500dm3/h and 100dm3/h.

The feed system is used for accurate, continuous volumetric and gravimetric feeding of bulk materials such as powders and granulate materials.

Read more

Multidos H- Continuous Gravimetric Feeding for Maximum Feed Rates

The MULTIDOS® weighfeeder can be used in an extremely wide variety of ways for continuous gravimetric feeding, and it excels due to its high level of accuracy of +/- 0.25%. It is integrated into the MULTIDOS® product family, with application-specific series to fit every need. The MULTIDOS® H series weighfeeders are suitable for applications with maximum feed rates, high bulk-density materials and extremely high removal moments with large silo discharge openings.

Read more

Multistream G-Solid Flow Meter for Continuous and Reliable Recording of Solid Material Streams

The continuous and reliable recording of material streams

The MULTISTREAM G is a compact in-line measurement system for the continuous recording of bulk solid streams using non-impact force measurement. The material stream is “gently” deflected via an in-line measuring chute. The system ensures that impact factors, which vary depending on the bulk solids, are not incorporated into the results.

MULTISTREAM G therefore generates better reproducible data to ensure product quality.

Read more

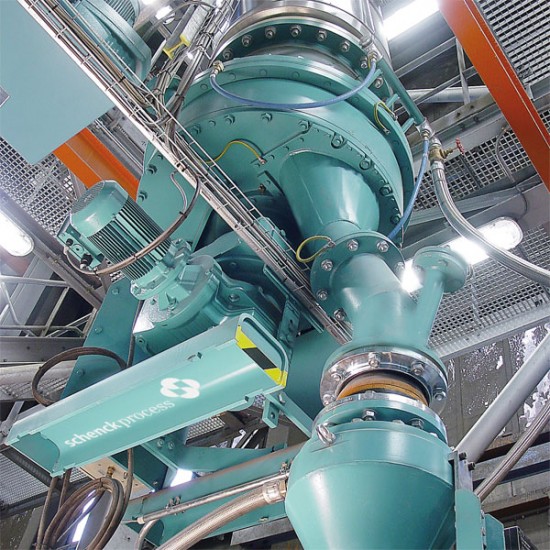

Multicor K and MULTICELL

An unbeatable team

Pulverized coal feeding requires economic efficiency, quality and maximum reliability. The parameters are based on the interplay of overall system engineering, material discharge, feeding and pneumatic material transport.

Optimal pulverized coal feeding in three steps

Perfectly matched system components are a basic requirement for optimal three-step pulverised coal feeding. This is realized in a pressure-proof mass-flow feed system using the Coriolis principle with a horizontal star feeder.

1. Pulsation-free silo extraction

Schenck Process Silo Engineering stands for mass flow at the beginning of the process chain. The large silo outlet and agitation system which is integrated into the horizontal star feeder ensures the homogenization of the material and its pulsation-free discharge from the silo.

2. Exact measurement – excellent feeding performance

The material flow is measured quickly and precisely using the Coriolis principle. It functions without being affected by any external influences. The MULTICELL horizontal star feeder’s speed control performs the direct mass flow measurement. This ensures that the actual feed rate exactly corresponds to the specified nominal value.

3. Pulsation-free transport

Our engineering ensures the ideal layout of the pneumatic conveyor line. The required amount of air and the conveyor cross-section are calculated to ensure optimal transport of the fuel from the feeder to the burner. The exact design pressure and intake volume of the blower are also determined.

Read more

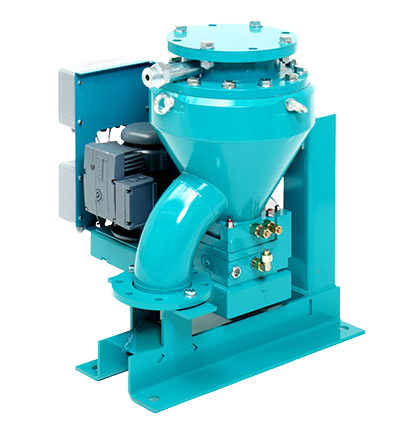

MULTICOR S- FEEDING OF POWDERED MATERIALS

A mass flow-rate feeding/dosing device according to the Coriolis principle

MULTICOR® S mass flow-rate feeding devices are used wherever large amounts of bulk solids need to be continuously established, controlled and fed. They provide precise feeding according to the Coriolis principle, a unique measuring principle for bulk solids based on direct, fast measured value acquisition.

Read more

Conveying Systems

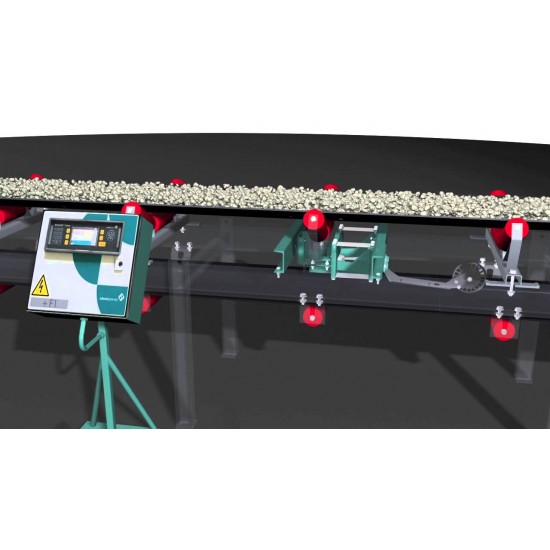

Belt Weigher Multibelt- Weighing on a Moving Conveyor Belt

Weighing on a moving conveyor belt

Flexibility is required to measure continuous, different material streams. This is a requirement which Schenck Process conveyor belt scales meet extremely well.

The right solution for every application

The applications include production and logistics, throughput and consumption rate measurement for production systems, internal balancing of supply and withdrawal, load limit signalling, batching at loading stations or pre-feeder control and legal-for-trade weighing. Schenck Process belt scales are as precise as required – with accuracies of +/- 0.5% when using a dual idler belt scale.

Read more

FulFiller C - High Speed Container loading system

High-speed loading for plastic pellets, grain, sugar etc.

Container loading made easy while also reducing time, costs and manpower in one and maintaining maximum efficiency. This is the promise brilliantly delivered at speed by the FulFiller C.

The technologies deployed are based on proven module solutions which allow for various, individually adapted forms of use.

Applications: filling granulate bulk material into ISO standard containers in the chemicals industry, in the production of polyolefins, in haulage and for example in the processing of grain and soya.

Read more

IntraBulk BRU- Bulk reception unit

The IntraBulk® reception unit is an above ground bulk material reception solution providing a user friendly, cost-effective alternative to conventional below ground intake pits. IntraBulk® BRU systems can create a marked reduction and significant cost reductions in areas with the need for expensive civil works, and across a diverse range of industries.

The IntraBulk® is capable of receiving bulk materials from a range of material handling vehicles, such as:

- Road tipping trucks

- Front-end loading units

- Walking floor trailers

The incredible diversity of the IntraBulk® offers complete material handling and reception units solutions for all needs.

Read more

MoveMaster- En-masse chain conveyor - Gentle handling of bulk materials

Gentle handling of bulk materials

MoveMaster® – The Mechanics of En-Masse Conveying and Elevating

En-Masse movement is the term used to describe the unique method of conveying bulk materials smoothly, gently and economically. Material is induced to move like a liquid through a slender dust tight steel casing, horizontally, on an inclined plane, vertically and around bends. The conveyor feeds itself at any point with a uniform load. The skeletal flight configuration induces the material to flow in a solid, placid column. There is no internal disturbance or pressure on the material and the load can be discharged at any opening, where it is permitted to fall away from the flights. The conveyor is not a scraper conveyor. There is no dragging or scraping action, material simply moves forward in a solid placid column, ‘En-Masse.

Read more

MoveMaster Vac - Vacuum Conveying Technology

Schenck Process Vacuum Conveying technology is used throughout the Food, Pharmaceutical, Chemicals, Minerals and Plastics industries to handle both raw materials and finished products.

The key components in a Schenck Process vacuum system are the pick up and reception points which are based on a modular construction with patented dust proof seals and quick release clamps to simplify cleaning or autoclaving. As a result, complete units can be stripped down in minutes.

The modular construction also means changing process needs can be readily accommodated by simply replacing the relevant standard components from the wide range available.

Read more

Screening & Separation

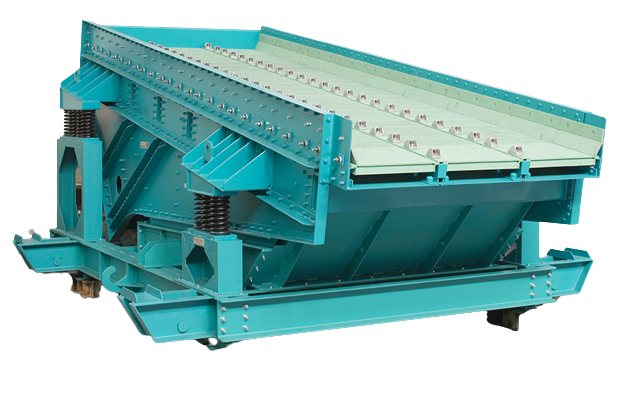

LinaClass SLG- Linear vibrating screen - Universal application, high performance

The Schenck Process LinaClass SLG linear vibrating screen measures 4 × 10 metres and is gigantic. It is the biggest Schenck Process screen ever built. Designed, assembled and tested by Schenck Process, Darmstadt.

What is a screen of this size built for?

In a nutshell, for the toughest requirements, for extreme environmental conditions and for difficult bulk solids with specific flow properties.

The screen was designed for the screening of cooled sinter at a feed rate of up to 450 t/h. The sinter is screened in advance and has a grain size of 0-10 mm. The fines are 0-5 mm in size, and the so-called returns are screened at an efficiency of around 96 percent. The high quality of screening required is guaranteed by the screening machine design and, moreover by the arrangement and type of screen panels selected.

Read more

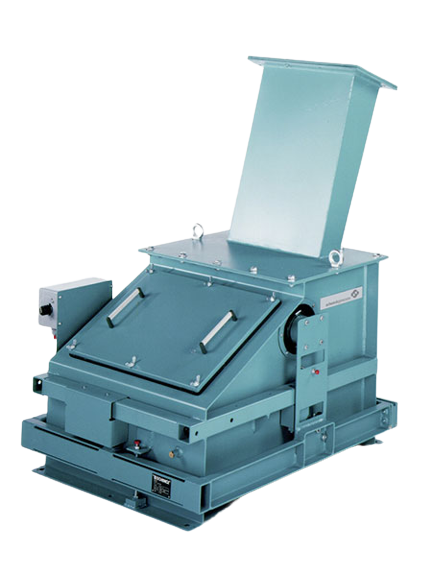

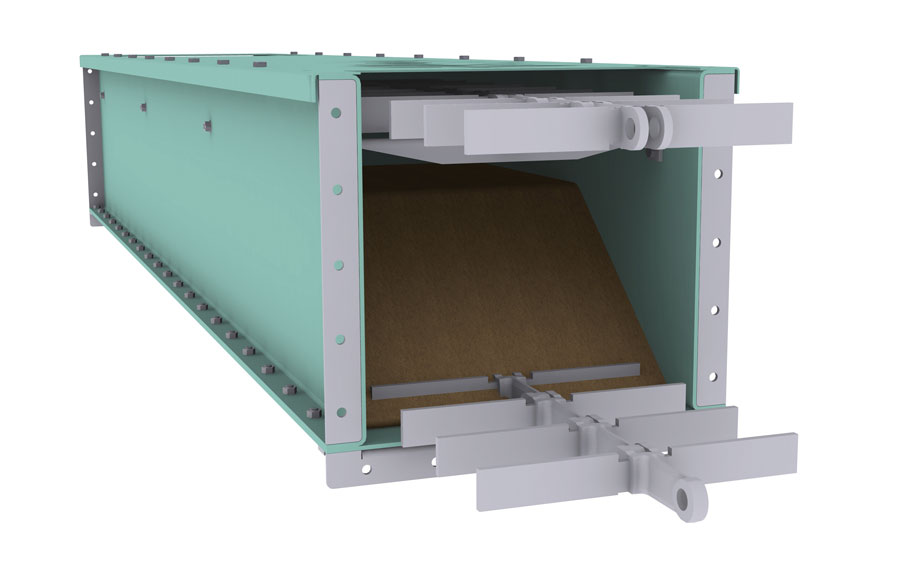

Vibrating feeder- for Discharging Bulk Solids from Silos

No easy task

When medium, heavy or extremely abrasive materials have to be transported over different conveyor lengths from silos or other storage containers.

Schenck's solution

Schenck Process offers the perfectly adapted solutions à la Carte for even the most demanding tasks– from individual solutions to individual components and product solutions.

Schenck Process vibrating feeders are preferably used for discharging bulk solids from silos. They transport medium to large material flows over conveyor routes of varying length. Even very heavy, highly abrasive materials can be discharged under the most difficult of conditions with the aid of our specially designed vibrating feeders.

Feeders with magnetic exciters, unbalance exciter or force exciters are used, depending on the application.

Read more

Automation

DFT-A weighbridge- Above-ground scales - Space saving & transferable

Space-saving & transferable

Flexible designed for use in changing locations

The above-ground version of the Schenck Process weighbridge is quite literally suitable for any relocation. It arrives at each usage site fully pre-assembled from high-quality precast concrete parts. A special feature is the pre-fitted, robust ring torsion load cell bearings.

All these features make very light work of moving this version of the weighbridge from one location to the next.

Further advantages:

Minimal construction work required on site. Kerbs for safely guiding vehicles.

Read more

LOGiQ- Loading automation system - Automated, flexible, efficient

The intelligent software LOGiQ is the first step in a new range of products. The software is middleware for automating the planning and loading of bulk materials and cargo. Although it is essentially suitable for any area of industry it is however primarily aimed at the cement, chemical and steel industries.

The software was developed using the Java programming language and can therefore be used with a wide range of operating systems. Java, alongside .NET from Microsoft, is one of two software platforms that have emerged in recent years and fulfil all the requirements of modern software solutions. The decision in favour of Java mainly came down to the fact that, unlike .NET, it is designed as an independent system. For a company like Schenck Process, which serves customers all over the world and needs to provide them with optimum solutions for different environments, this is a crucial requirement. With Java, developers can create software for very different operating systems.

Read more

Weighing Electronics & Software

INTECONT Tersus- Ultra-modern, compact and multilingual

The INTECONT® Tersus offers unrivalled performance and state-of-the-art features.

Among other things, the INTECONT® Tersus is characterised by its ultra-modern display technology. A colour high-resolution display and extreme operating convenience make it one of the most modern machines on the market. The event marking and entry assistance colours provide the user with valuable support.

Thanks to the comprehensive range of operating languages, the INTECONT® Tersus can now be used to suit customer requirements the world over. The electronics are accommodated in a control panel rack and can be integrated in a wall housing. The basic machine features an Ethernet network connection. Fieldbuses can be installed for perfect communication.

Read more

INTECONT Opus- Analysis system for legal-for-trade belt scales in the 0.5 accuracy class Software

INTECONT® Opus offers user friendliness and precision in the 0.5 accuracy class

What would weighing and feeding technology be without precise analysis systems? The answer is obvious – and Schenck Process, the global market leader in measuring and process technology, is regularly spurred on to deliver the best performance in this area.

Read more

LOGiQ- Loading automation system - Automated, flexible, efficient

The intelligent software LOGiQ is the first step in a new range of products. The software is middleware for automating the planning and loading of bulk materials and cargo. Although it is essentially suitable for any area of industry it is however primarily aimed at the cement, chemical and steel industries.

The software was developed using the Java programming language and can therefore be used with a wide range of operating systems. Java, alongside .NET from Microsoft, is one of two software platforms that have emerged in recent years and fulfil all the requirements of modern software solutions. The decision in favour of Java mainly came down to the fact that, unlike .NET, it is designed as an independent system. For a company like Schenck Process, which serves customers all over the world and needs to provide them with optimum solutions for different environments, this is a crucial requirement. With Java, developers can create software for very different operating systems.

Read more

LOGiQ- The integrated logistics solution for no-touch yard management

The LOGiQ system provides a seamless logistics solution for smooth and efficient yard management. Its fully automated and integrated structure makes loading or unloading trucks an effortless process with only minimum employee intervention.

From the minute an authorized truck approaches your premises through entering the yard, doing initial weighing, loading the right amount of materials, exit weighing and then leaving your yard, the LOGiQ system takes care of all the steps. LOGiQ ensures that all information is ready at hand, collects and processes driver and order data, and feeds everything into the underlying IT system (e.g., SAP) in real time.

Thanks to fully automated processes, you

- optimize cycle times

- reduce labor costs

- provide fraud protection

- access actual sales and management data in real time

- minimize yard traffic and efficiently allocate interim parking spaces