Universal Balancing Machines

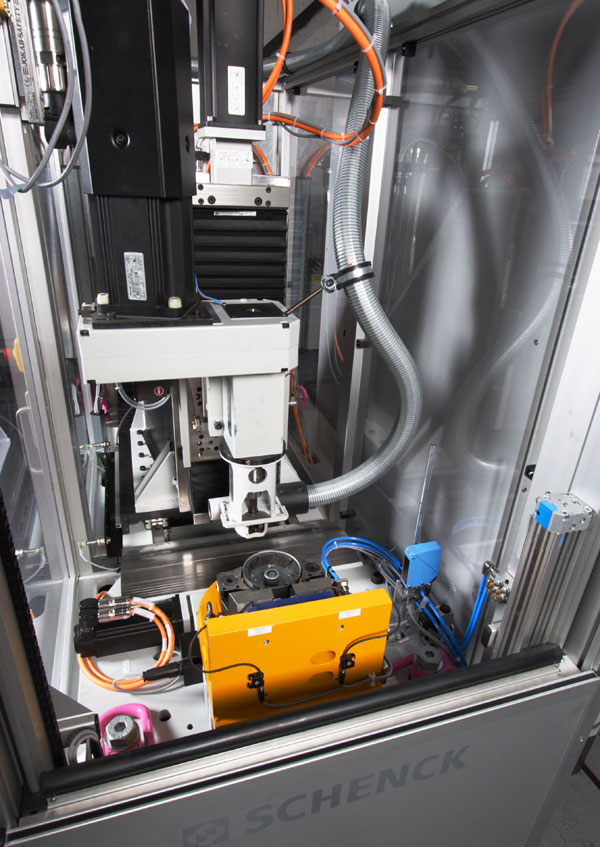

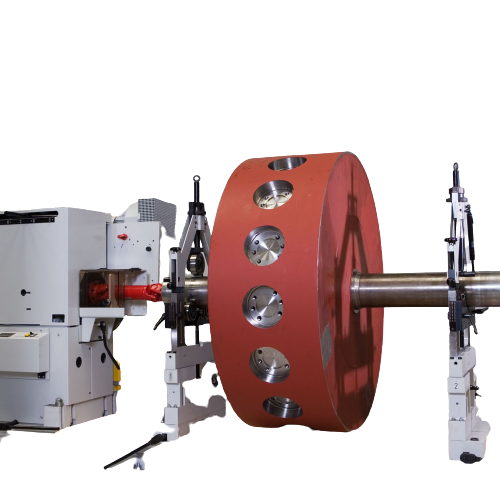

Pasio- a New Generation of Compact Balancing Machine

Pasio 5/05/005 - Excellent for small rotors up to 5 kg

Pasio- a New Generation of Compact Balancing MachineThe smallest Pasio series is a completely new design. The revolutionary design concept contributes to efficient workflows of the table balancing machines and offers a host of advantages to the users: It provides easy access to the workspace, the measuring device, and all other important control elements. Its optimized Human-Machine-Interface ensures error-free operation and fast set-up while taking up a minimum amount of space. The compact Pasios feature an excellent measurement accuracy, which ultimately saves you time and money, since a single measurement run and correction step is enough in most cases to ensure that the rotor is within the tolerance.

Read more

Pasio 15 - Wide Rotor Range up to 15 kg

The Pasio 15SC is always the right choice when you want to perfectly balance a wide spectrum of rotors up to a maximum weight of 15 kg. The current model is also equipped with the advanced Save Control, which permanently coordinates and monitors many of the machine functions. It always keeps you updated on the status of the Pasio 15SC and lets you react individually.

Read more

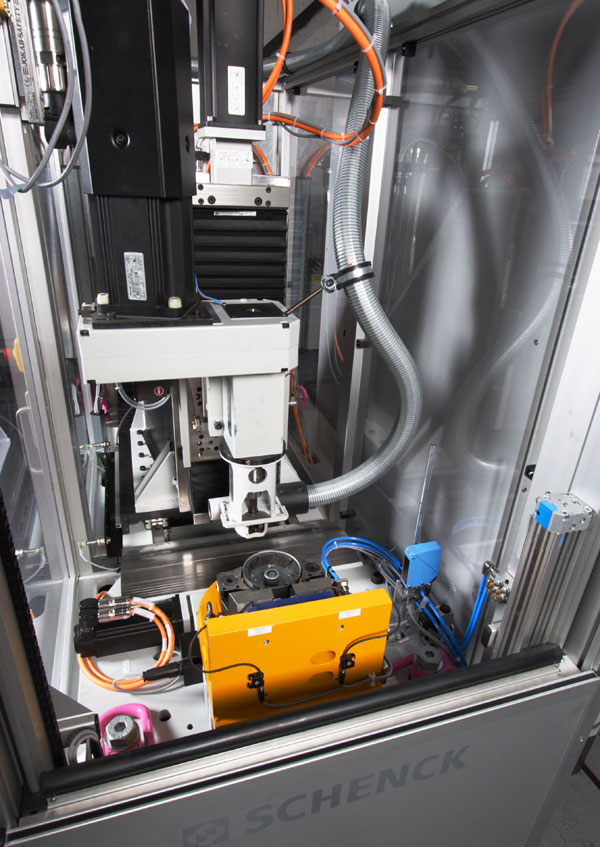

Pasio 50 - Balancing of Drive Elements down to Gears

The Pasio 50SC is the second generation of SCHENCK RoTec large Pasio series. It is designed for rotors up to 50 kg with a maximum rotor diameter of 600 mm and a length of 1,000 mm. It covers a practical rotor range frequently found in production plants and repair facilities. Sophisticated mechanics and perfect measuring technology permit residual unbalances of less than 0.5 gmm per plane and therefore a very high unbalance reduction ratio.

Read more

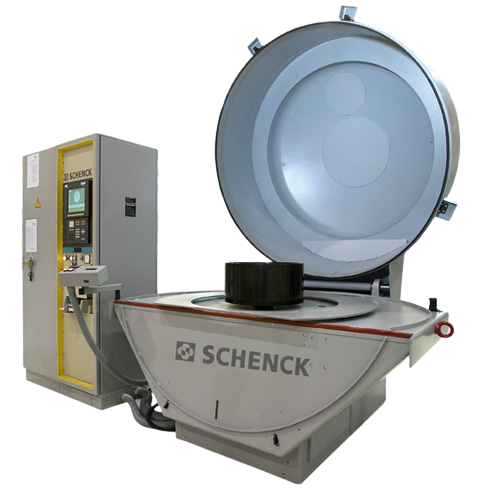

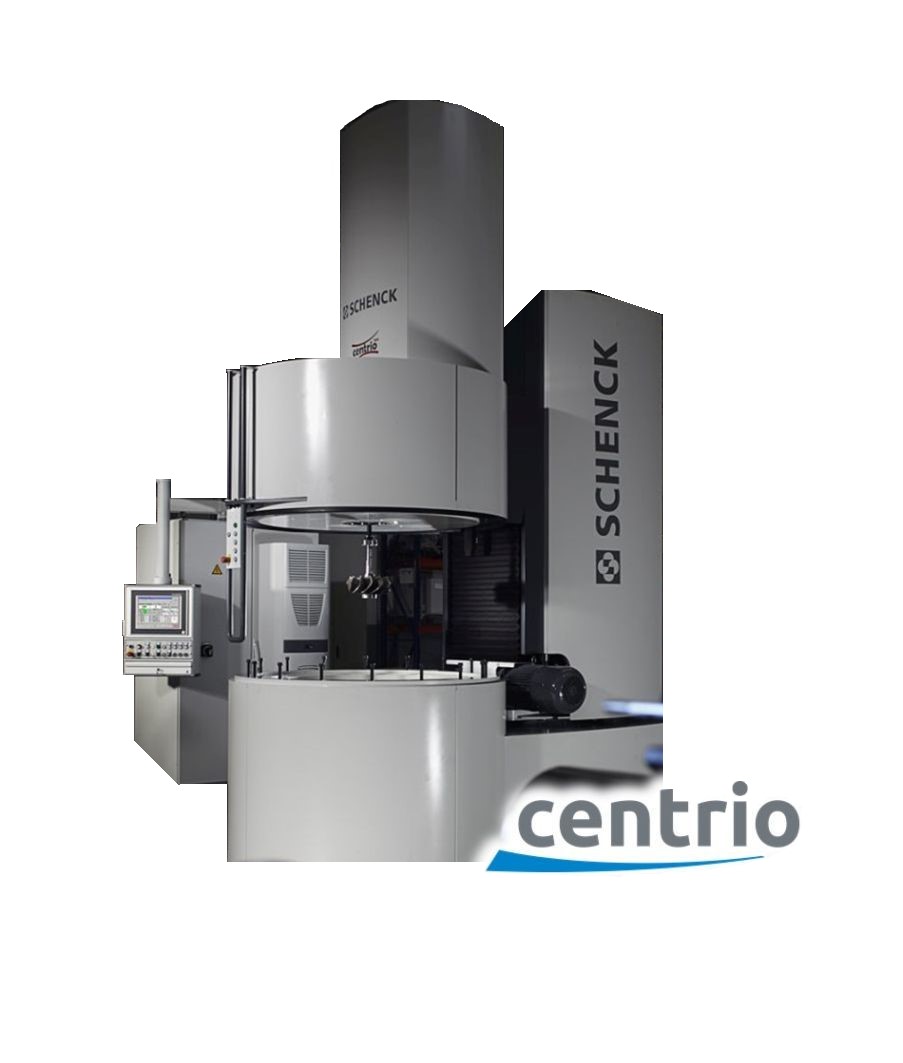

Virio- the new vertical balancing machine for rotors up to 300kg

Virio is a vertical balancing machine which is easier to operate, with improved accuracy and offers you even greater flexibility.

The benefits at a glance:

- Compact design

- Ergonomic operating concept

- Versatile correction procedures

- Infinitely variable speed regulation

- Easy installation

Read more

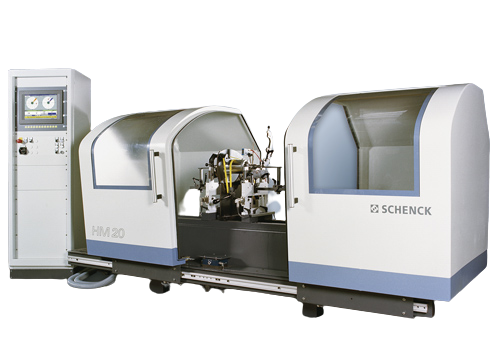

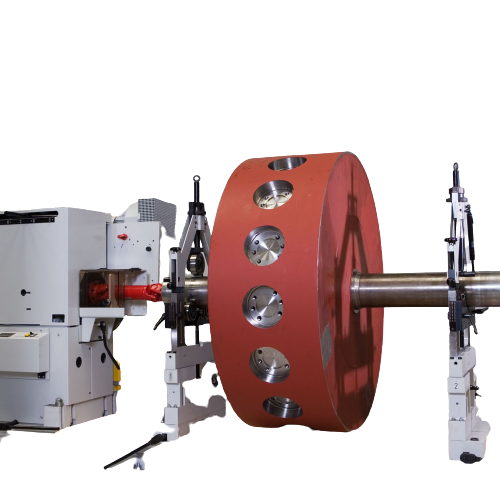

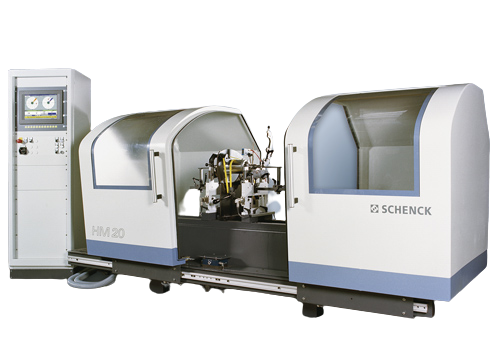

Horizontal Machines Series HM

HM 20 - HM 30

- Universally applicable

- High balancing accuracy

- Easy upgrading through modular structure and a wide range of accessories

- Hard-bearing principle ensures fast change-over

- Measuring instrument CAB 820, optional CAB 920 - the high end solution

- Extensive safety equipment for all protection classes

Read more

HM 4 - HM 50

- Universally applicable

- High balancing accuracy

- Easy to upgrade through modular construction and a wide range of accessories

- Hard-bearing principle ensures quick change-over from one workpiece to the next

- Measuring instrument CAB 820, optional CAB 920 - the high end solution

- Full range of safety equipment for all protection classes

Read more

HM 6 - HM 80

- Universally applicable through modular design

- Safe handling through economic design concept

- Full range of safety equipment for all protection classes

- Easy change-over to different rotors

Read more

Vertical Machines Series SVM

Automatic Vertical Balancing Machines- 150 SVM, 151 SVM, 350 SVM, 550 SVM

- Fully automatic operational sequence

- Manual loading and unloading

- Interfacing with production line is possible

- Fully automatic unbalance correction by drilling, milling, welding or riveting

- Analog or NC axis controlled correction

- Digital measured data processing

Read more

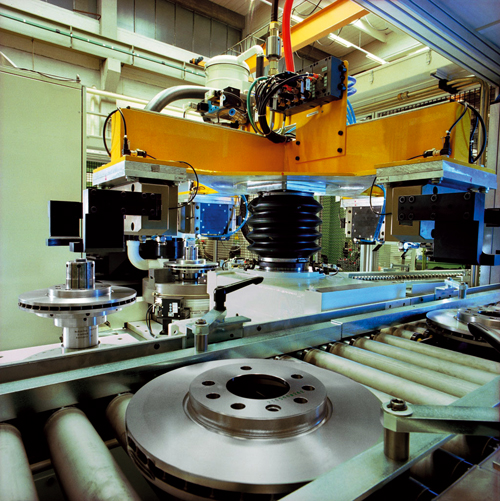

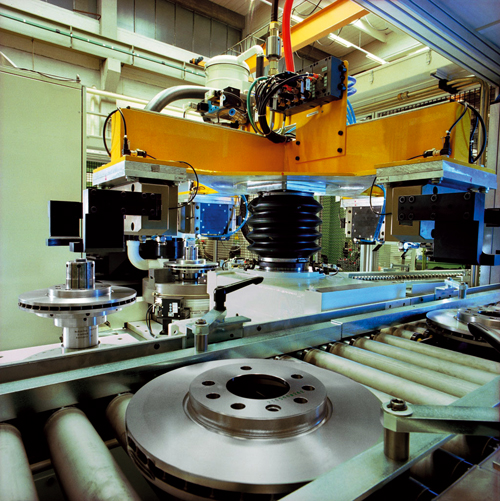

Vertical Balancing Machines- 450 SVM, 452 SVM, 453 SVM, 454 SVM

- Fully automatic function sequence

- Manual and automatic loading and unloading

- Integration with production line

- Fully automatic unbalance correction by milling

- Correction control by NC axes

- Digital measurement data processing

- No hydraulic

- NC controlled power chuck for clamping the brake discs during correction

Read more

Static Machines

Measurement of the static unbalance of disc-shaped rotors, e.g. unhardened grinding wheels, propellers and fans. Unbalance correction by addition of material directly on the machine or by removal of material on separate correction units. Use of the machine for the measurement of unbalance, for tasks with unbalance correction in production, in incoming inspection, for final balancing and for weight measurement.

The advantages of static machines ESA & ESF:

- No mechanical influences on the rotor during measurement

- Determination of unbalance and rotor weight

- Simple and low-cost rotor adapters

- No drive system and no protection device required

- Short measuring times

- Powerful PC based CAB 920 measuring unit with TFT screen

- 2 versions available:

- Table-top version

- Enclosure-mounted version for large rotors

Read more

TARO- Static Balancing Machine

- Without rotation – simple and precise balancing

- Rotor weight from 200….3.600 kg

- Determination of unbalance and rotor weight

- No drive and no safety device required

- Short measuring times

- Efficient measuring unit CAB 920; operation by Touch Screen

Read more

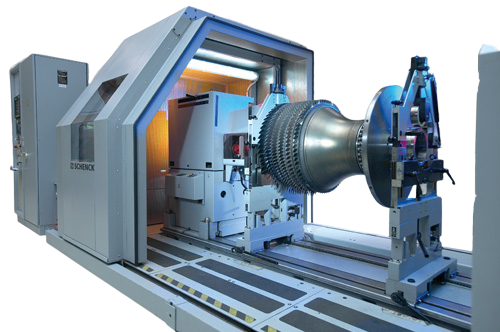

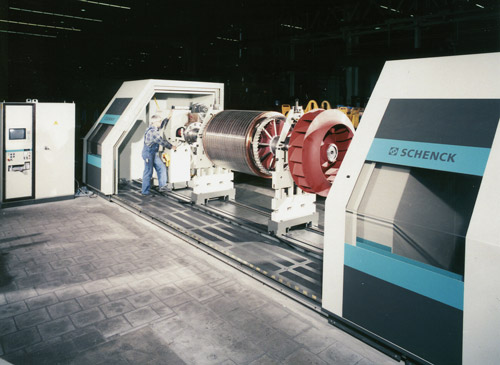

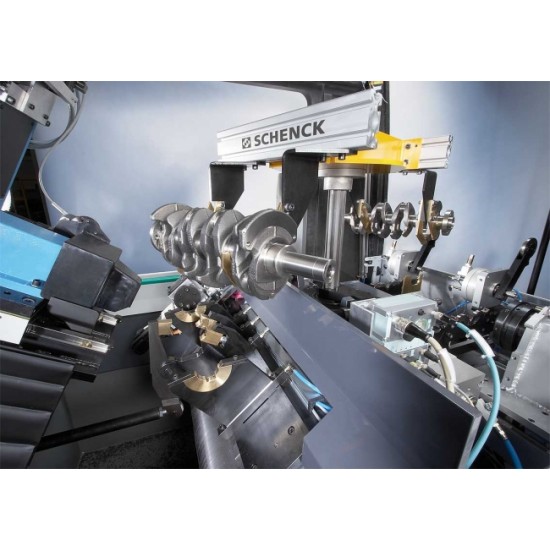

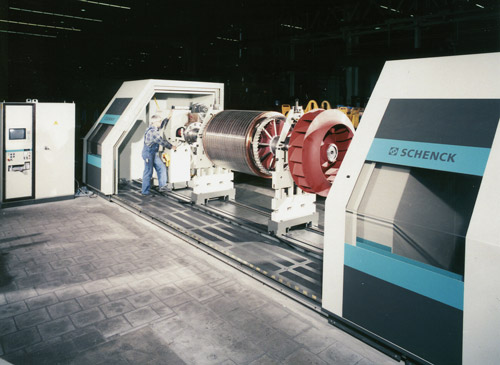

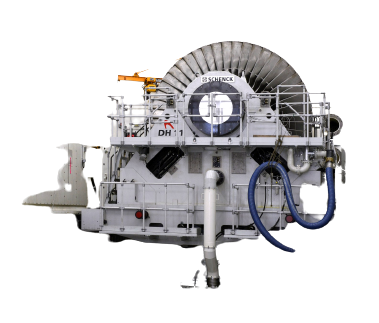

are used for balancing of large power plant turbines and generators, high-speed compressors, industrial steam and gas turbines and complex testing of jet engine components. In a constant exchange of experience with our customers, we are developing the balancing facilities and special bearing pedestals of the DH series.

are used for balancing of large power plant turbines and generators, high-speed compressors, industrial steam and gas turbines and complex testing of jet engine components. In a constant exchange of experience with our customers, we are developing the balancing facilities and special bearing pedestals of the DH series.