Plastic & Rubber

Measurement & Inspection Systems

Process Equipment for Plastic Plants

Balancing in Tire Plants

Plastic & Rubber

Performance materials

Bioplastics- Putting the most accurate green solutions in your hands

Best-in-class solutions for unrivaled accuracy, quality and reliability

Whether it’s single-use packaging, films, or biodegradable straws, the quality of the products that come off your line depend on the quality of your processes. And it’s the industry-leading accuracy of our solutions that give you the precision control you need to deliver the quality finishings your customers expect. With 30+ years of bioplastics expertise, Qlar can tailor solutions to meet your every need, from unloading and granulation to compounding and dust collection – all with the trademark reliability their systems are renowned for.

Read More

Compounds- Qlar make high quality compounding effortless Precision systems for the perfect mix

Precision systems for the perfect mix

Accuracy is everything in compound mixing – and it‘s exactly what our world-class handling equipment is engineered to deliver. Qlar's precision process solutions ensure your product colors and surfaces perfectly meet the specifications and consistency standards you and your customers require. Their specialists tailor your process and equipment needs to your unique site and material demands – with long-term stability and maximum operational reliability the cornerstones of every system they design.

Read more

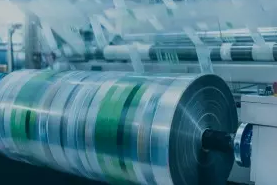

Film- New films for new times Qlar's professional team are experts in modernizing your processes

Qlar's professional team are experts in modernizing your processes

Film is in flux. On the one hand, its main purpose of protecting goods is unquestionable- and there is a trend for film to replace rigid plastic formats. On the other hand, its sustainability is challenged by consumers and legislators- leading to the growth in use of more recycled and recyclable materials. Whichever way you look at it, the evolution of plastic film making requires expertise in process optimization and modernization. Providing this expertise is what their experts do.

Read more

Masterbatch- Extruding imagination

Qlar keep creativity and innovation flowing – with precision and flexibility

In the masterbatch sector you never stop developing. You keep on creating new colors and functional or decorative additives to inspire the world’s product designers and consumers. To deliver this magic two factors are essential: Absolute precision in weighing, feeding, and conveying; and flexibility in the set-up of production lines. Qlar can contribute to your precision and flexibility- thanks to our broad experience in end-to-end performance material handling systems and a strong installed base across the world.

Read more

Polyolefins- Delivering the highest standards of finishing your customers expect

Best-in-class solutions for unrivalled accuracy and quality

Whether it’s plastic bags or moldings for the car industry, the quality of the products that come off your line depend on the quality of the processes they pass through. And that’s where the industry-leading accuracy of Qlar plastic processing solutions make all the difference. They give you the precision control you need to always deliver the levels of quality color and surface finishings your customers demand. With Qlar's deep application know-how and end-to-end bulk handling systems, they can tailor solutions to meet your every need for plastic granulation, compounding and beyond- from unloading to conveying and dust collection.

Read more

Recycling- Taking care of even your most hard-to-handle materials

Qlar got all your bulk material recycling needs covered

With 20 years of experience as partner to some of the world’s biggest recycling facilities, Qlar have the specialist expertise to help you solve any recycling challenge you can imagine. Especially when it comes to handling difficult materials such as PET flakes, glass fibers and regrind. Their market-leading solutions for materials from plastic to rubber encompass everything you need across the entire process chain – including bulk bag unloading, pneumatic conveying, feeding and a full range of dust collection equipment to keep your plant safe from harmful airborne materials.

Read more

Tires & Rubber- Enhanced rigor for your flexible materials

Qlar's perfect solutions for rubber processing

Rubber is an extremely complex material, sometimes blending up to 20 materials in comparison to 3-4 for plastics. So precision is essential- even when making a simple gasket, never mind a modern tire, with its innovative mixes of chemistry, physics and engineering. Qlar's rubber processing equipment gives you the accuracy you need to handle the most complicated tasks. They are experts in pneumatic conveying, dust collection, weighing and feeding technologies.

Read more

2D/3D Measurements with Laser Profile Scanner

Laser scanners from Micro-Epsilon are among the highest performing profile sensors in the world with respect to accuracy and measuring rate. They detect, measure and evaluate profiles on different object surfaces without contact. The available models are suitable for numerous industrial applications. The integrated intelligence in their sensor head (scanCONTROL SMART) solves versatile measurement tasks. Models for the customer’s own programming are available for integrators. The scanCONTROL profile scanners do not require any external controller.

Read more

View Micro-Epsilon's variety of applications for 2D/3D laser scanners

Measurements for the Plastic & Rubber Industry

The plastics area requires all kinds of measurements. Whether on final products such as motor vehicle tires, during the production of different compounds in the extruder or already previously during the manufacture of different pellets and additives. The thickness of the product itself is frequently measured instead of displacements and distances. On the other hand, distances and temperatures on the production systems are often measured.

Micro-Epsilon offers a wide range of sensors and solutions for non-contact measurement of plastics production. Dimensions, thickness, temperature, colors and embossing patterns in roll or sheet form can be reliably measured in a wide range of process steps from extrusion via molding to further processing.

Read more

Measuring and Inspection Systems for Rubber and Tires

The rubber processing industry, as well as the tire production process is supported by Micro-Epsilon with a range of systems for inspection, monitoring and control of miscellaneous processes.

Read more

Measuring and Inspection Systems for Plastics

Gauges and inspection systems from Micro-Epsilon are used in the plastics processing industry in order to ensure efficient production.

Application fields:

Film extrusion

- Thickness profile measurement of blown films (non-contact and contact measurement 10µm to 500µm)

- Thickness measurement in flat film extrusion lines (thickness 30µm to 6mm)

- Non-contact thickness measurement of thermoformed flat films (thickness 0.1mm to 6mm)

- Non-contact thickness measurement in hot melt calender lines (thickness 30µm to 6mm)